Since the beginning of Karün, we have been in a constant search for materials that can be part of our products and that hopefully are generated in Patagonian communities. Following this path the last few years we have been working strongly with wood and plastics recovered from disused nets and ends.

Since last year, we’ve been thinking of a new material, metal. Why metal? On one hand, we want to be able to offer products of very good quality and diversity in order to reach more people, and in order to have a broader portfolio, where all people can find something that suits them according to their taste and identity, we believe it is fundamental to integrate more points of view into our community and invite more people to see the world from another point of view.

On the other hand, and the most important reason, is due to the impact this generates: throughout the world, a lot of metal of different types is used, such as beverage cans, preserves, household appliances, bodywork, tools, among many others, and large quantities are discarded and end up visually and environmentally contaminating nature, since the minimum time in which this type of material degrades exceeds 35 years. This reality is not alien to what happens in the rural communities of Patagonia with which we collaborate. After a work of recognition of their needs in terms of waste, we have identified that they coincide in the identification of metals as one of the waste materials that are generated and that are improperly disposed of in the area. Aluminum cans left by the locals, tourists and visitors, old cars that due to lack of options, the neighbors end up burying in their yards, are some of the testimonies we have collected and that show a strong/felt need to take care of these materials.

Facing this reality, we asked ourselves if it was possible to dream of metal glasses in our collections, through which we could contribute to promote a waste collection system for recycling in the commune of Cochamó, in a four-year plan that we are working on together with our social and local allies.

Starting a collection design process and including new materials is not an easy process, since each material is different in its composition, use, and treatment, which requires a learning period to ensure that the product that comes out of the process maintains the quality that characterizes Karün glasses and to ensure a raw material collection chain that respects the basic principles that characterize us, which include collectors and local rural entrepreneurs who can either recover the material from the territories we want to protect and preserve, or from sources of recovered and recycled material.

If we wanted to graph in a simple way the main stages that we consider our process of manufacturing on sunglass, we could summarize it in the following stages:

- Identification and characterization of raw materials: we focus our work to get the majority of our raw materials from organic, inorganic, or residual materials from Patagonia, if this is not viable (due to the type of material or the requested quantity) it Is complemented with other sources that must ensure its source to be recovered and recycled. The recovered raw materials must comply with suitable mechanical characteristics for the fabrication of the product to be designed. In this stage, first, a sweep of the available waste material is made, and then there is a study of materials, identifying those that we can use from those that we can’t.

- To design a product that is attractive to our customers and that ensures ecodesign, that considers an environmental improvement of the product and in the whole manufacturing process, considering a minimum impact on the environment from; its creation to its end of life. For this, we consider that the product to be designed must be manufactured with recycled or reused raw materials, that it is durable (of good quality, sustainable in time), and that after its useful life it can be recycled.

- Validation and tests carried out with the factory, where the feasibility of fabricating the glasses is determined and the quality obtained is evaluated. After several tests and adjustments, the final product is obtained with the specifications of the suitable materials to be considered in the process.

- With clarity on the material to be used, a chain of the raw material collection is formed with rural or local collectors, and the communities who will be the key link in our chain, to ensure that the material is collected in a socially, environmentally and economically responsible manner.

- Preparation of the material to be used in the manufacturing process and subsequent shipment to the corresponding factories.

If the previous stages are measured in time, this exceeds 12 months or even 18 months of work, therefore, if we wanted to follow each of these stages, we were sure that we would not be able to respond to the urgency of having a new metal collection and respond to the needs raised by the community, who are with all their energy put into initiating actions that allow them to recycle the metallic material that is generated year after year in their communities.

Faced with this challenge, we have traveled a path that has led us to propose a process in stages to build our metal chain that respects the Karün principles and way of working.

Metal gathering compensation

What do we mean by compensation?

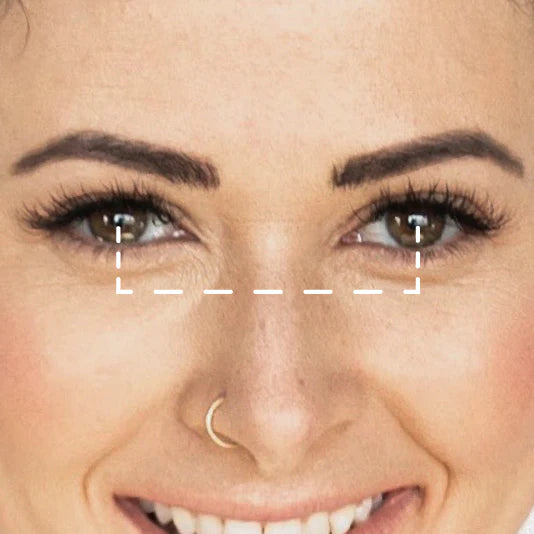

The process in which all the volume of recycled material (in this case metal) that is used in production comes from local sources and recyclers to the production and at the same time in Patagonia, exactly the same amount and type of material used in production is collected, in this case, Copper, aluminum and Stainless Steel. In summary, the metal recycled from the product is from local sources to the factory, which goes through a 7-stage process: sorting; disassembled and cut; dust removal by vibration; washing and drying; pressing; melting; molding. On the other hand, the material collected in Patagonia is recovered and delivered to companies that support its subsequent recycling. The result of this Compensation model is a process that generates twice the work of restoring natural spaces but with half the impact on the Carbon Footprint.

Another challenge that we find in the manufacturing of glasses with recycled metals, is to incorporate into the industry this type of raw material with these characteristics, since to this date, it is almost impossible to find recycled metals suppliers that can satisfy the technical needs required by factories to produce this product.

Thanks to a great effort from our partners factories in China and South Korea, we were able to find a supplier that could meet these requirements, but it is in the process of obtaining certifications to back up its recycling process. At the same time, we keep searching for new supplier alternatives that can provide this type of material to our production line.

By compensating we want to go further, so we put together 3 fundamental principles to strengthen our impact:

- We always recover the same type of material that is used in the glasses.

- We promise to recover the same or a greater volume than what we require to manufacture the product.

- According to the trade local prices of the material that we need, we have paid at least 20% over that purchase price.

- In this way, we build a more robust source of income for our collector friends.

If you have questions or suggestions you can write to us at info@karunworld.com or contact us HERE.

If you have questions or suggestions you can write to us at info@karunworld.com or contact us HERE.