A great crisis without a paradigm shift is one of the saddest images we can imagine. It implies that the problem, with the wounds that it always implies, did not bring learning with it. That idea keeps our eyes wide open in order to be able to take in all the knowledge possible in real time to apply it to the emergency situation we find ourselves in today. The need for regeneration in nature drives us every day to generate changes and seek new ways to contribute to the future of the planet.

And how can we help generate this change from a company that produces eyewear? By proposing a different model to think, produce and consume. Because we are confident that through fundamental changes in these processes, the necessary paradigm shift can be achieved to face the climate crisis.

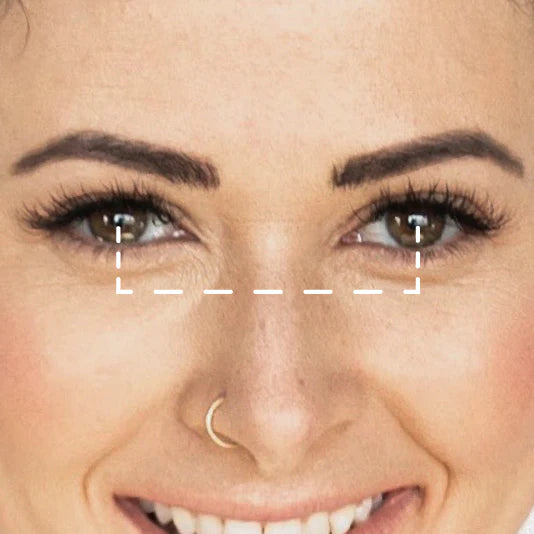

In addition to the Karün Conscious Development Model that we have been working on for the last decade, this year we have launched a transparency initiative that completely changes the way we understand the impact behind each Karün product. And it's there where we would like to generate a change, in the understanding of its impact and communication. How? We have measured and labeled the carbon footprint of each product (you can read more about our CO2 measurement and labeling here) and we have also developed a Responsive Web Platform for the management and traceability of the supply chain. From the origin of the raw materials, through each link in the ecosystem of our collaborating partners and suppliers, to the final product.

“Knowledge is power” said Sir Francis Bacon and he was not wrong. Data today is powerful and allows us to understand, empirically, what until today in most companies and industries is a big black box. And no problem can be solved until we can delimit its contours and transform it from something vague into something concrete and observable. Where does the raw material for my product come from? How many miles did it have to travel to reach its production plant? Did it go through one or multiple plants to become what it is? Where were these plants? This proprietary traceability system empowers the client and certifies the answers to all these questions through Blockchain.

There are two applications that make up the solution:

-

Karün Backoffice: responsive web platform that manages all the information necessary to feed the traceability system. Here, our team can upload information about the different steps involved throughout the eyewear manufacturing process, from the collection and recycling of materials to distribution. Some selected transactional data in this process is protected using blockchain technology.

-

Karün Traceability System™: a responsive web application that allows Karün customers to track their eyewear throughout the production process, interacting with a map and with the different links on it, accessing multimedia content that illustrates each development participant during the journey.

And what need is there to occupy Blockchain? This technology allows us to assure the client, through external validation, of all relevant transactions within the back-office application. To do this, a blockchain API located in an A1 AWS (Amazon Web Server) is invoked in order to persist and secure each transaction executed by the back office system. At this address, back office users within Karün will be able to save and secure information related to the different steps involved:

-

collected lots

-

recycling lots

-

Production batches

-

distribution lots

In addition, the application provides input for the multimedia content associated with each link, in order to display this content in the traceability system. So you can see and connect with audiovisual content of collections in Patagonia, plants, recycling centers, etc.

Why all this effort? So you can make informed purchasing decisions. And also to encourage the rest of the industry to join. We want to inspire and catalyze the commitment of companies so that, together, we can change the parameters with which consumers can choose a product and, as a consequence, reduce carbon emissions globally.

Customers deserve to know how their purchases impact the environment and we have made it our mission to do everything we can to push this paradigm shift. Even so, traceability has complex streaks, which are difficult to deal with at the beginning. It implies revealing what is good and, also, what today is not up to the level we are looking for. There are elements that we are infinitely proud of and others that we believe have opportunities for improvement. In any case, we are happy, we want to make the success and the deficiencies transparent. We want to know in detail and show everything we can because we know that in this way, and only in this way, can we improve. What is observable is optimizable, so the logical thing would be that tomorrow this new paradigm would generate synergies that may allow companies to learn from each other on this path of transparency to improve our processes, giving us knowledge that translates into more options and better ways of dealing with production.

Easily comparing products based on your practices and processes would be a highly desirable new standard. And, to the extent that traceability becomes more widespread, this will create a race for constant improvement to reduce the impact of products, which would also be a tremendous achievement. But, for that, we need to be more. If only a handful of companies publish the data, it becomes profoundly difficult for consumers to decode this data and make decisions based on it. They need points of comparison to be able to know if process X is more or less desirable for the planet than process Y. Only if we manage to push transparency and traceability to become the new standard for companies, could this become a radical act.